Constructing energy-efficient houses contributes to saving energy and mitigating adverse environmental impacts. Increasing energy efficiency in Georgia is critically important in the villages where, based on the current social and economic situation, access to energy sources is limited.

Village residents primarily use wood as their main heating source. According to the National Statistics Office of Georgia[1] and CENN,[2] wood consumption has reached 2-3 million cubic meters in the past three years. Unsustainable logging on a massive scale inevitably leads to negative impacts on forests and ecosystems. Therefore, taking appropriate measures and actions to increase energy efficiency and to reduce energy consumption in terms of heating in the villages is crucial.

Increasing the energy efficiency of wood is possible by drying wood, using energy-efficient ovens, thermal insulation of houses, etc. This article examines the potential of thermal insulation by utilizing plastic waste to insulate village homes. Before evaluating the use of thermal insulation, it is worth it to note the following positive effects of the aforementioned technology:

- Reducing plastic waste and the amount of plastic waste disposed of in landfills;

- Increasing the number of thermally-insulated buildings;

- Reducing imports of expensive insulation materials;

- Reducing overall wood consumption.

According to a Dutch organization, Huys Advies,[3] insulating a house using plastic waste is a successful practice in a number of Asian countries, especially in mountainous regions with severe winters where the amount of plastic waste is increased due to a large influx of tourists.

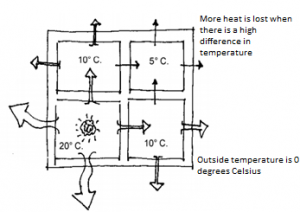

Regarding the method of thermal insulation, its operation is especially efficient using PET bottles. It is essential that used PET bottles are washed and dried thoroughly, because wet bottles generate moisture that naturally reduces thermal insulation when in contact with heat. The higher the moisture level in the walls of a building, the higher its thermal conductivity and, consequently, the lower its thermal insulation capacity. To better comprehend the method, view the illustrations below indicating heat losses at different temperatures. Alternatively, in poor thermal insulation conditions, heat loss in the building is greater.

Thermal insulation utilizing PET bottles is less thermally conductive than walls made of concrete or brick which prevents heat escaping from a heated building.

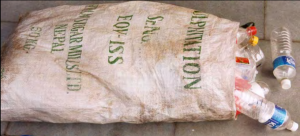

Thermal insulation from PET bottles is possible to implement with used fiber sacks. Used PET bottles without caps must be inserted into a sack; sack thickness depends on the outside temperature and ranges from 5 cm to 15 cm.

These sacks can be used for thermal insulation of a ceiling, walls, as well as the roof and floor. It should also be noted that using PET bottles in the above manner poses no health hazards as the PET materials do not degrade and emit harmful substances.[4]

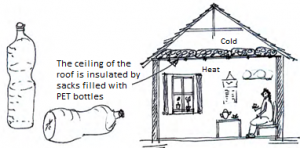

The greatest heat losses occur during the poor thermal insulation of a ceiling, since the heated air moves from the bottom upwards. Therefore, ceiling insulation is important for building insulation. The illustration demonstrates the possibility to insulate a building using sacks filled with PET bottles.

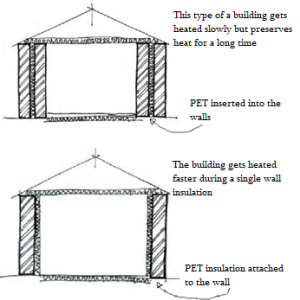

The given method is applied in a different manner in the case of wall insulation. There are two main methods: insulation utilizing PET bottles inserted into a double wall, and regular internal insulation of the wall.

A building where insulation is installed into double walls heats up slowly, but preserves heat for a longer period of time since the walls first heat up and then the heat is conserved by the insulation.

In contrast, a room with single wall insulation heats up faster because there is less to heat.

It should be noted that insulation can be applied to both constructed buildings and new buildings in the process of being built. All parameters and optimal alternatives must be considered, in order for the homeowner to make an informed decision that best suits their needs.

Using PET bottles for thermal insulation is a cheap technology. The investment cost is approximately five times cheaper than that of traditional thermal insulation materials. Furthermore, it has a significant heating value and reduces energy costs by 30-35%.

[1] Georgia energy balance, GEOSTAT, 2015, 2016, 2017.

[2] CENN, Consumption of firewood in Georgia, Assessment of Demand, Supply and Potential, 2016.

[3] www.nienhuys.info

[4] Thermal Insulation for House Construction with Used PET Bottles, Huys Advies, 2004.