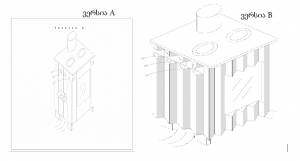

Georgian and European specialists are working on new models of solid biomass furnaces adapted for local production and consumption. Unlike the European model, the round tubes in the furnace casing are replaced by a rectangle, which makes it easier and simpler to manage the enterprise process. Most importantly, Georgian entrepreneurs will be able to make the product in simple mechanical workshops.

The developed models are designed with a zigzag wall and squares placed in it with beams, which significantly increases the thermal conductivity of the furnace, and improves its cost-effectiveness and performance. In addition, such an approach allows the serial production of different variations (different design, capacity, functions) with compatible details. At this stage, innovative prototypes are being piloted at the production base of the New Technology Center. Serial production of energy-efficient stoves will be possible after successful testing. Furnace certification is also planned.

The initiative to develop energy solutions in rural areas aims to reduce energy pressure in forests and replace low-efficiency stoves with modern and comfortable heating means. The program is implemented in the format of public -private partnership and combines several donor projects: ” Efficient wood-burning stoves for Mtskheta-Mtianeti ” (implementer – Agora CE , financial support – UNDP with the financial support of the Ministry of Foreign Affairs of the Czech Republic); “Sustainable forest management for rural development: (implementer – CENN, financial support – Austrian Development Cooperation (ADC);

This innovative technology is made possible because of ESCO Ltd. engineers: Abesalom Gvatua, Goga Giorgobiani, Ketevan Rekhviashvili and the opinions of their Czech counterpart, Radek Suda.